Rapid Prototyping Services: More Than Just A Trend

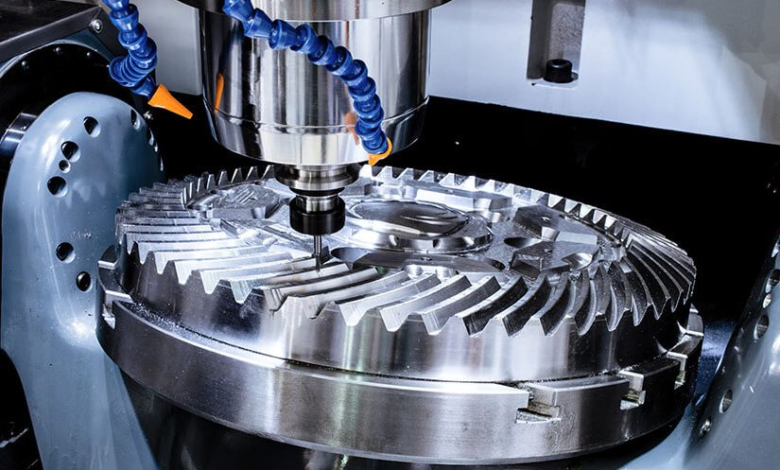

Rapid prototyping is a manufacturing technique for product models, specific parts, and assemblies. You can verify whether your product applies to the market through product prototypes and corrections to the product design.

Benefits of Rapid Prototyping Services

Rapid prototyping services are becoming increasingly popular, not just as a trend but for good reason. They offer several benefits that can make your project go much smoother:

– Reduced development time: Rapid prototyping can help speed up the development process by providing you with a working model of your product sooner rather than later.

– Reduced risk: By quickly creating a prototype, you can test your idea’s viability before investing additional time and money. If the prototype fails to meet your expectations, you won’t lose too much time or money.

– Improved communication and collaboration: Because prototypes are interactive, they allow you to communicate better with stakeholders and collaborators. This way, everyone knows what they need to know to make an informed decision about whether or not to invest further in your project.

– Flexibility: Prototypes can be changed or updated based on feedback received during testing, which allows you to ensure that your final product meets everyone’s needs.

Advantages of Prefabricating Parts on a Computer

Prefabrication has been around since the industrial revolution and is a Manufacturing process where parts are manufactured ahead of time in various shapes and sizes. One big advantage of prefabricating features on a computer is that it can save time and money.

Prefabricated components can be quickly assembled into a final product with better accuracy and consistency than traditional manufacturing methods. Not only does this improve the quality of the end product, but it also eliminates errors that can occur during conventional manufacturing processes. Additionally, using prefabricated components conserves resources, making them more economical to produce.

Pre-fabrication offers other advantages as well. For one, it allows products to be customized to specific needs or requirements. This is particularly helpful for unique or difficult-to-produce items like medical devices or aircraft engines. Pre-fabrication also makes integrating different types of technologies into products easier, which can help reduce costs and make products more user-friendly.

Disadvantages of Prefabricating Parts on a Computer

Prefabricating parts on a computer has several disadvantages:

- It isn’t easy to make the pre-made part fit exactly the way that you need it to. This can be because you cannot see or access all of the inside details of the part.

- If you need to make modifications to the pre-made part, it will be difficult and time-consuming to do so.

- If something goes wrong with the pre-made part, you may not be able to fix it or replace it easily.

Conclusion

Rapid prototyping (RP) is a technology that has been around for quite some time, but it seems to be growing in popularity more and more each year. This is likely because RP allows companies to quickly and easily test their ideas before committing resources to them. Additionally, RP can save time and money by allowing companies to create prototypes without building them from scratch. Rapid Prototyping Services may be a good option for you if you’re looking for ways to streamline your processes or reduce costs.

KAIAO is a professional technical enterprise providing customers with new product design stage verification, trial production, and low-volume production of your parts.